Aluminium forging

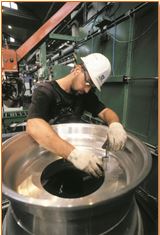

Alcoa wheel manufacturing process starts with a single block of high-strength, corrosion resistant aluminium alloy.

With an 8000-ton press, the block is forged into the wheel shape. Once forged, the wheels are heat-treated to maximise their overall mechanical strength.

Forging aligns the grain structure of aluminium with the shape of the wheel even in the most essential wheel rim and wheel disc contact area. This produces wheels with unrivalled strength that pass the most demanding TÜV, JWL-T, and LBF tests.

Precision machining ensures that each wheel is perfectly round. This eliminates any run out in a turning wheel.

Next, the ventilation and mounting holes are drilled.